New Option!

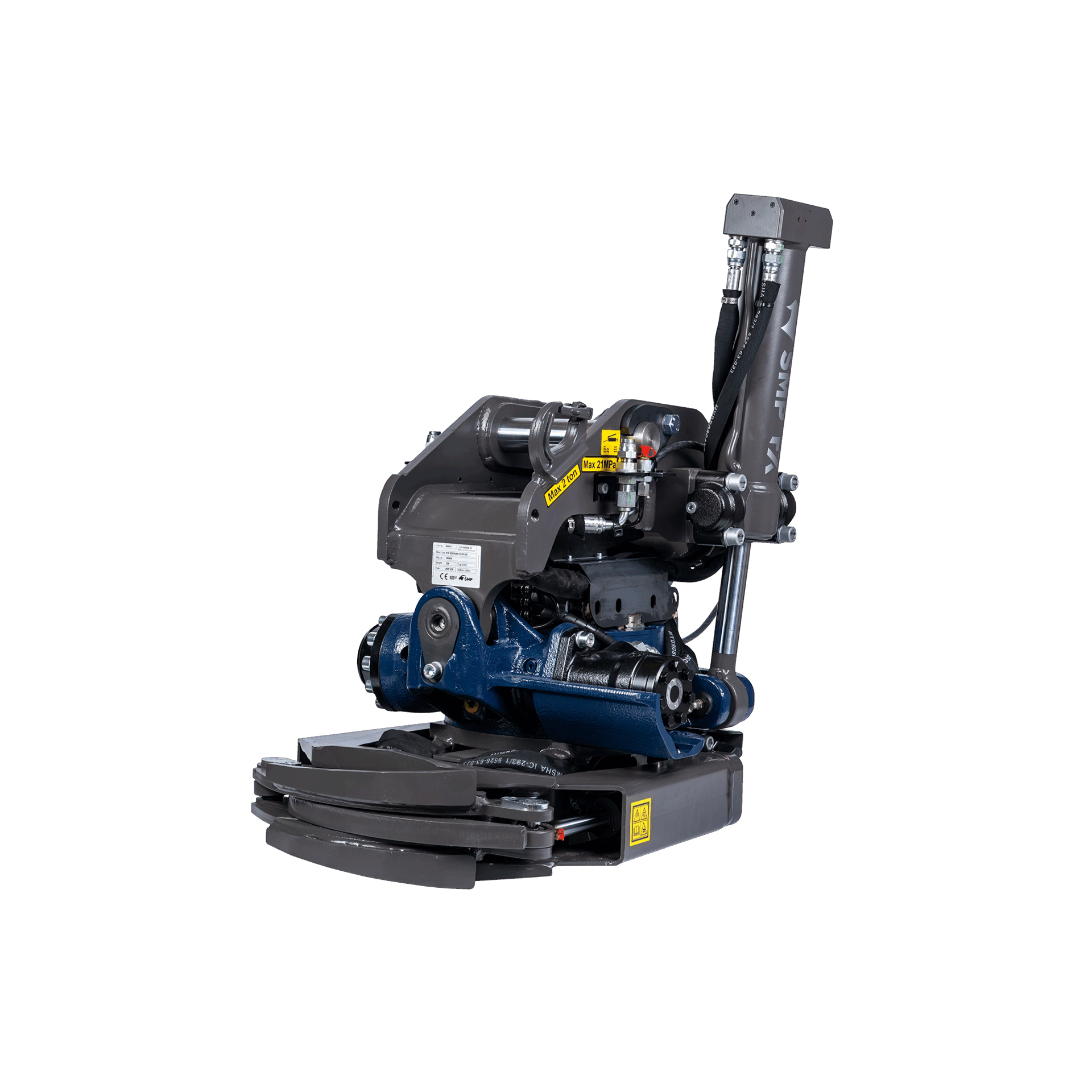

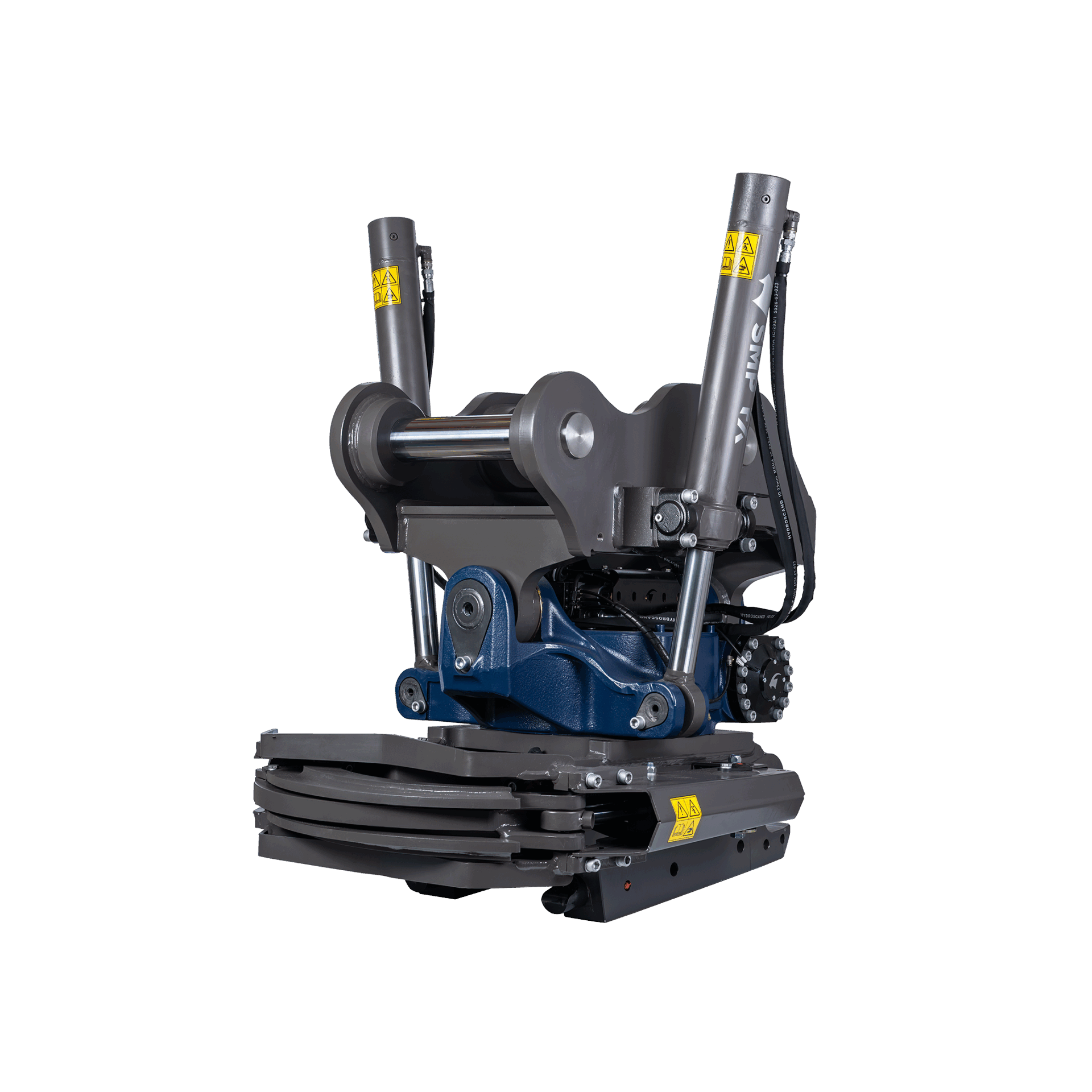

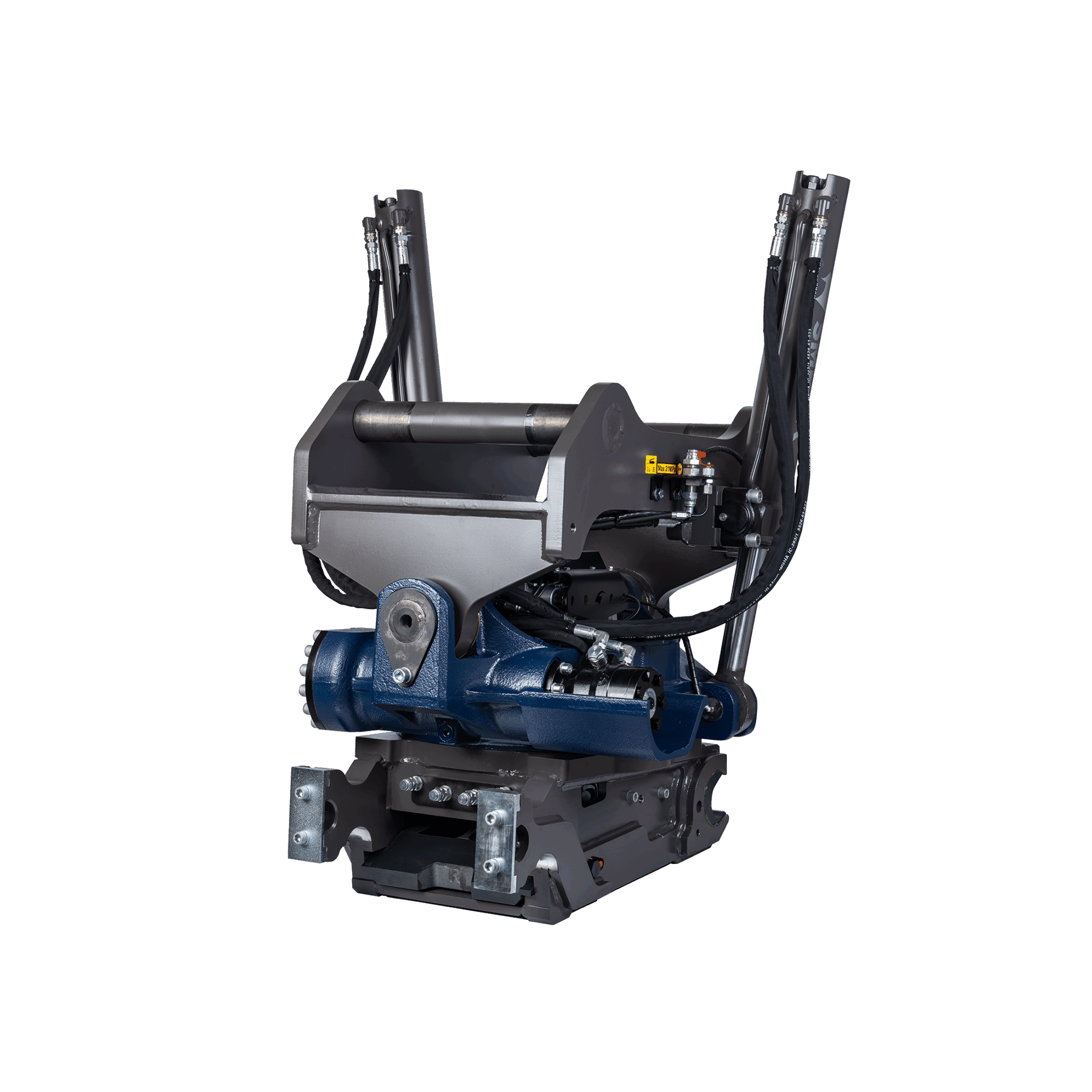

High Flow Swivel

for ST15-28

The new high flow swivel comes with a dedicated drain line as standard and can be optionally equipped with an electric swivel for low-power signals. The new swivel allows for flows of 200L/min in bypass configuration, providing full compatibility with flow-demanding tools such as sweepers, compactors, mowers and more.

The electric swivel is designed to transfer signals from control systems and intelligent tools.

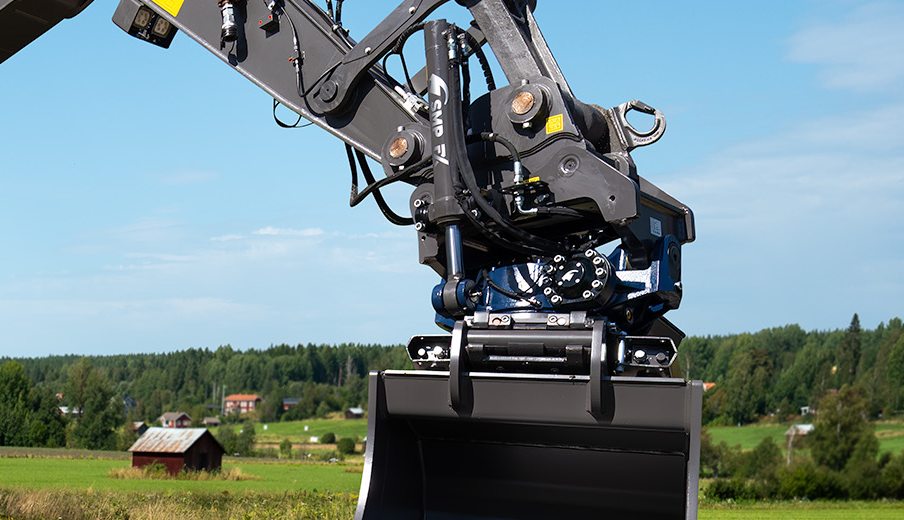

The FX series combines improvements to

the motor, cylinders, valve block, and rotation sensor.

Product improvement

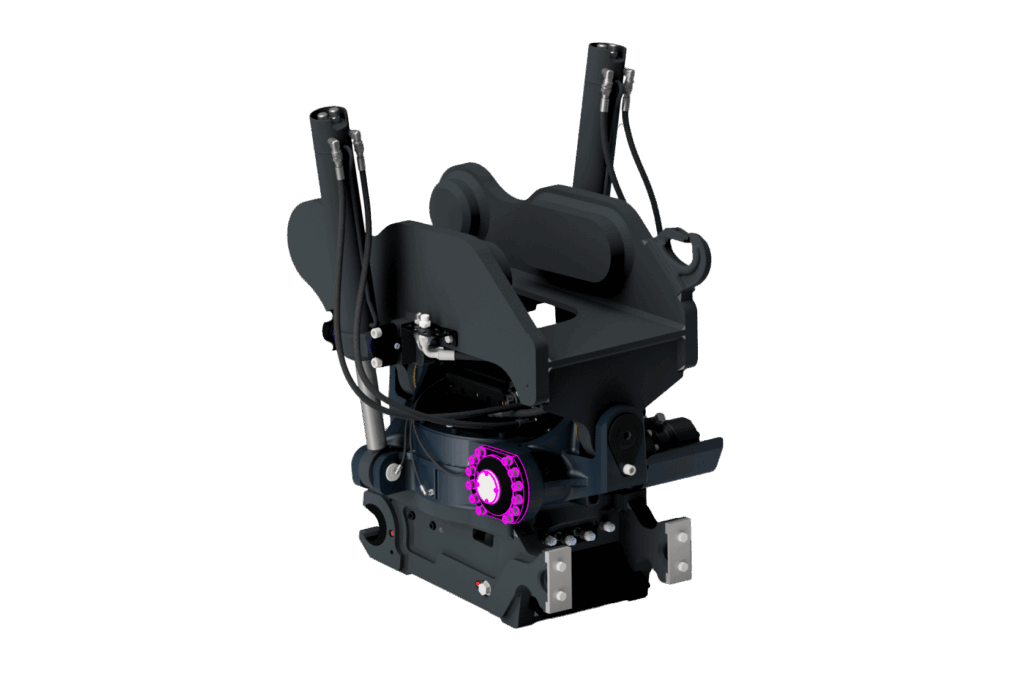

Rotation Sensor

A new, more robust rotation sensor was designed to improve reliability and performance. The redesign includes a new bearing support. Backwards compatible without software update, it will require a new bearing support on older units.

For older devices, a new bearing support will be needed.

Product improvement

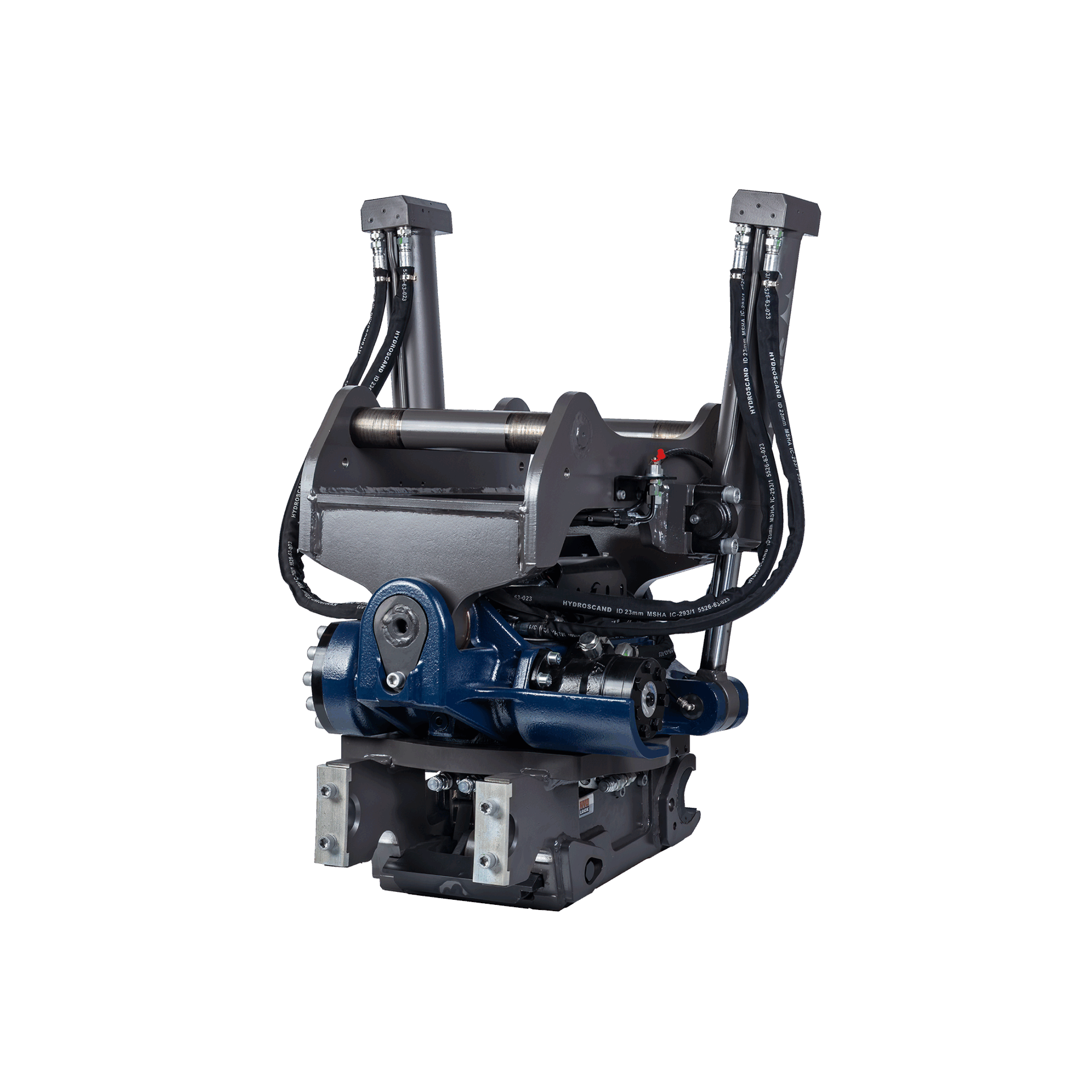

Valve package

The valve pack has been redesigned to accommodate the mentioned changes, and larger internal channels have been engineered to improve hydraulic efficiency. On the ST18-28 models, the previous two-piece valve pack has been converted into a single block.

This reduces the number of components, improves reliability, and increases performance. Finally, thanks to efforts in standardization and simplification, standardized hose kits have been developed. This allows for higher quality, more consistent assembly, and easier spare parts provision.

Productimprovement

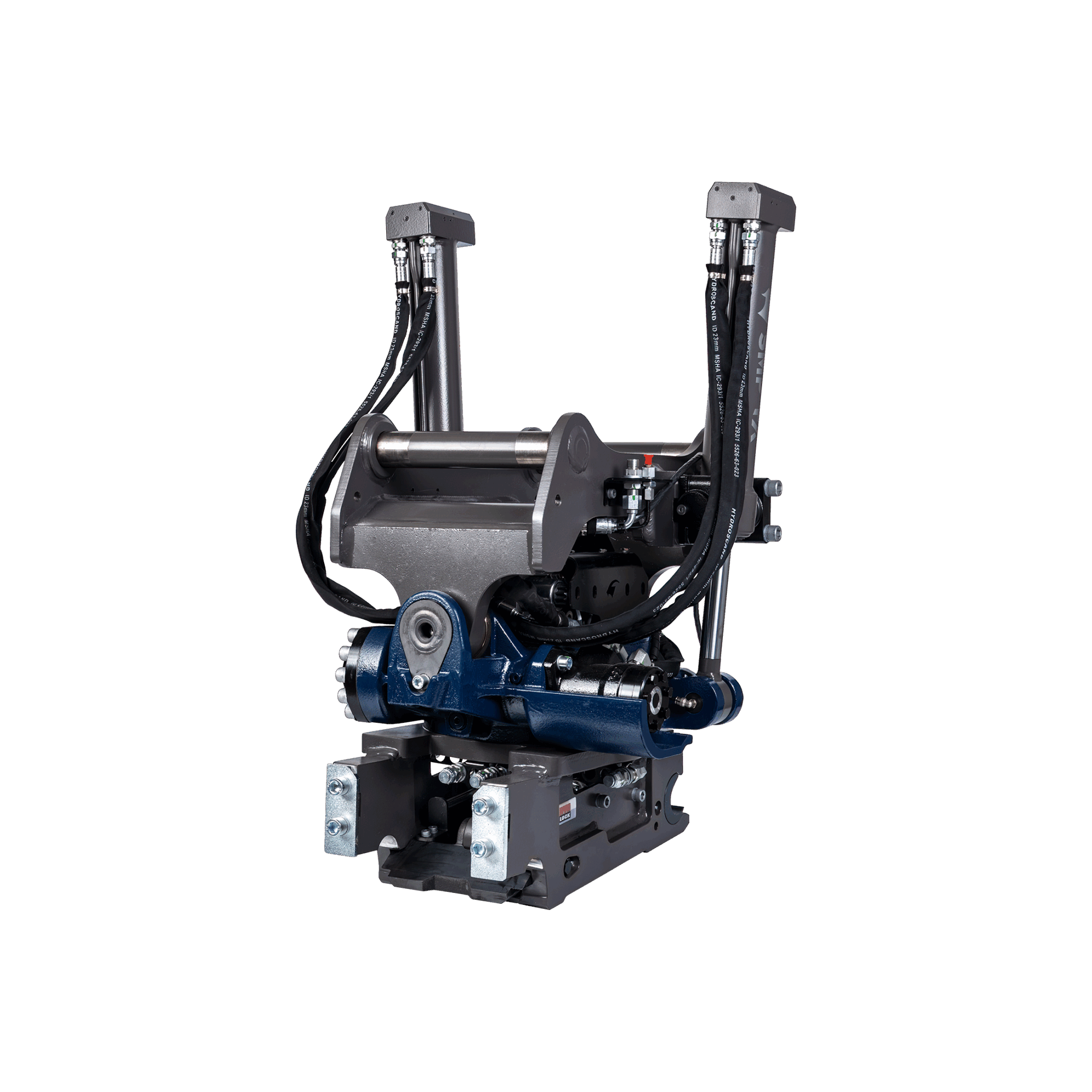

Tilt cylinders

The tilt cylinders, in both standard and telescopic versions, now have a directly mounted load-holding valve on the cylinders themselves, instead of in the valve block. This improvement increases both performance and reliability while further simplifying the valve block.

Productimprovement

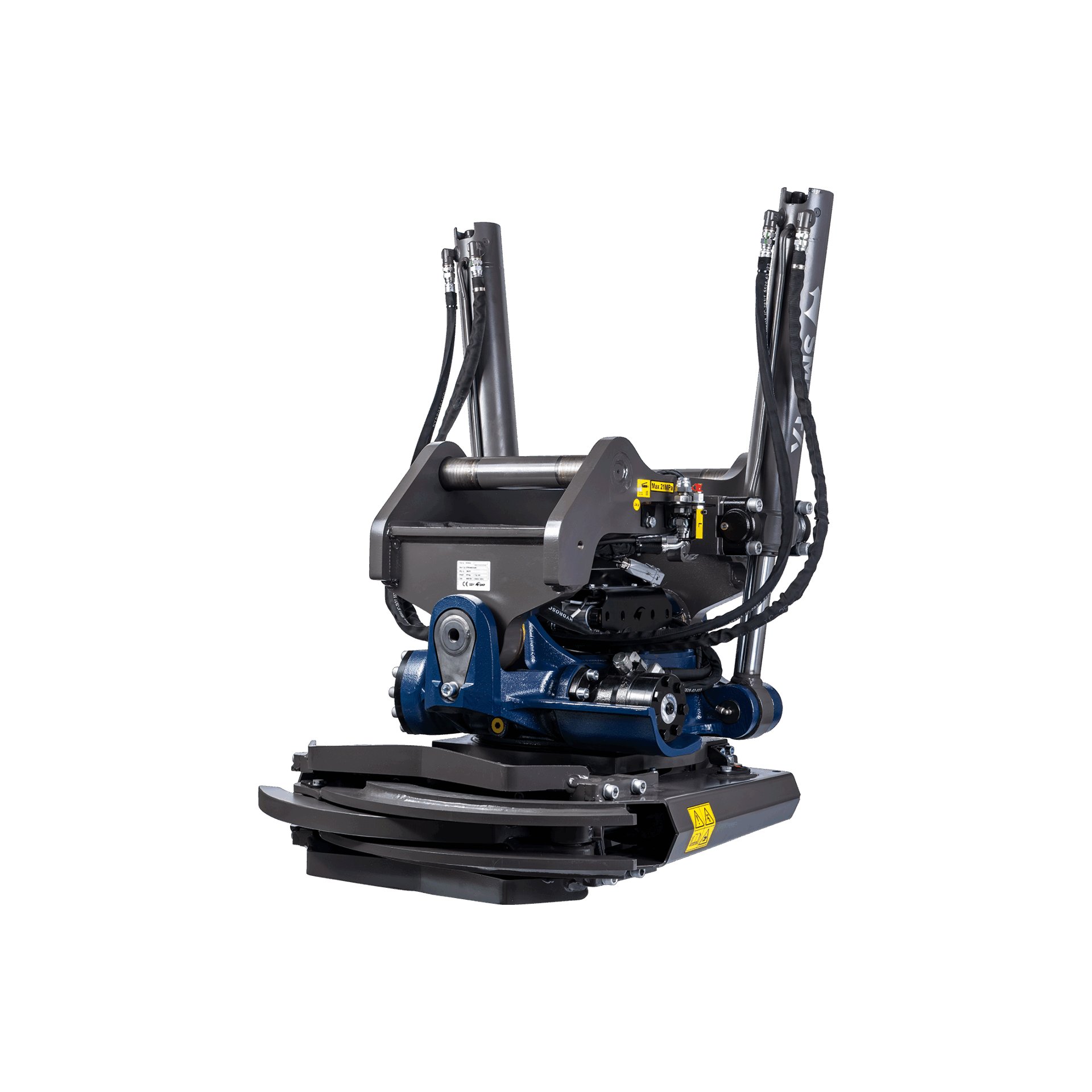

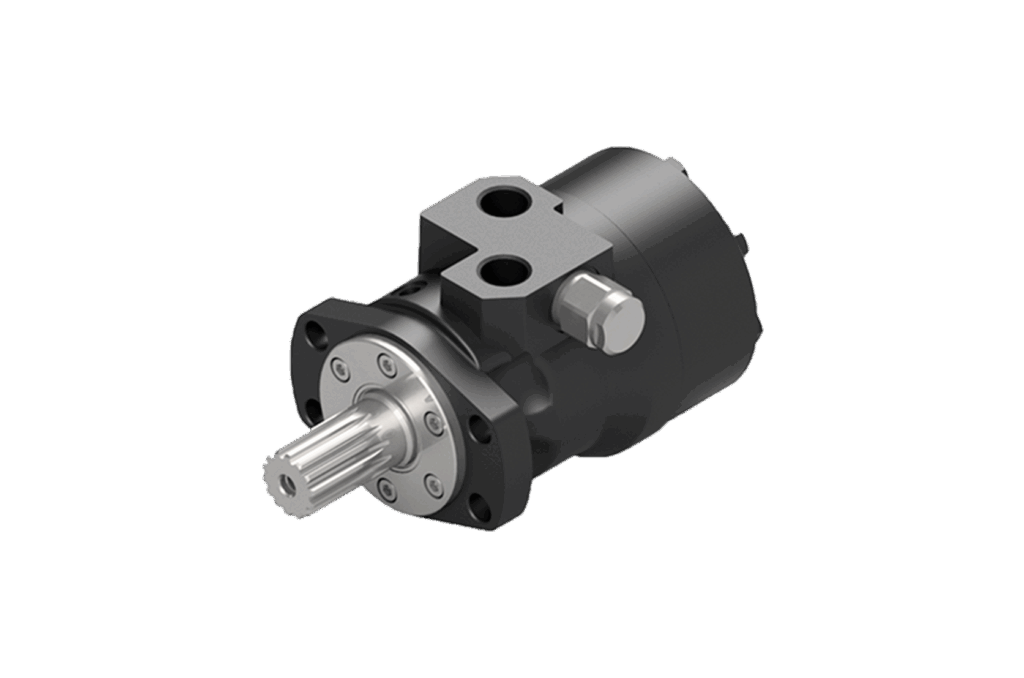

Hydraulic motor

We have redesigned the hydraulic motor to now include a pressure relief valve (PRV). This valve diverts high-pressure oil to the return line, effectively protecting the motor from dangerous pressure spikes that can occur when using wide buckets or heavy loads. By moving the PRV from the valve block to the motor, we improve both performance and reliability.

Additionally, this simplifies the valve blocks—they are now identical for all models from ST10 up to ST28.

The new motor can be retrofitted to older tiltrotators. In these cases, a plug is used to block the PRV mounting position, as older tiltrotators already have a PRV in the valve block.